Introduction to Water Treatment Equipment

we kindly provide customer different capacity (1 ton ---50 tons /hr) RO water treatment system to purify water for drinking.

Water treatment equipment plays a critical role in ensuring access to clean, safe, and sustainable water resources for various applications, including municipal, industrial, agricultural, and residential use. These systems are designed to remove contaminants, improve water quality, and address specific challenges such as hardness, pathogens, chemicals, and suspended solids. Below is an overview of common types of water treatment equipment and their functions:

1. Pre-Treatment Systems

-

Screens and Sedimentation Tanks: Remove large debris, sand, and suspended particles through physical filtration or gravity settling.

-

Coagulation/Flocculation Units: Add chemicals to clump fine particles into larger aggregates for easier removal.

2. Filtration Systems

-

Sand Filters: Use layers of sand and gravel to trap impurities.

-

Activated Carbon Filters: Adsorb organic compounds, chlorine, and odors.

-

Cartridge Filters: Employ replaceable filter elements to capture fine particles and microorganisms.

3. Water Softeners

-

Utilize ion exchange resins to remove calcium and magnesium ions, addressing hard water issues that cause scaling in pipes and appliances.

4. Disinfection Equipment

-

UV Sterilizers: Use ultraviolet light to inactivate bacteria, viruses, and other pathogens.

-

Chlorination/Ozonation Systems: Introduce chlorine or ozone to kill microorganisms and oxidize contaminants.

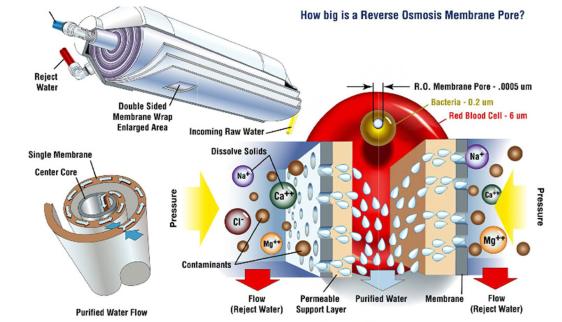

5. Membrane Technologies

-

Reverse Osmosis (RO): Force water through semi-permeable membranes to remove dissolved salts, heavy metals, and pollutants.

-

Ultrafiltration (UF): Block colloids, bacteria, and macromolecules using fine-pore membranes.

-

Nanofiltration (NF): Target divalent ions and organic matter while allowing some minerals to pass through.

6. Desalination Systems

-

Convert seawater or brackish water into freshwater via thermal distillation or membrane processes like RO.

7. Wastewater Treatment Units

-

Biological Reactors: Use microorganisms to degrade organic pollutants.

-

Sludge Dewatering Equipment: Reduce moisture content in waste sludge for disposal or reuse.

8. Advanced Oxidation Processes (AOPs)

-

Combine ozone, hydrogen peroxide, or UV light to break down complex organic pollutants and pharmaceuticals.

9. Water Recycling Systems

-

Treat and repurpose greywater or industrial effluent for non-potable uses like irrigation or cooling.

Key Benefits

-

Health Protection: Eliminates harmful contaminants to meet drinking water standards.

-

Environmental Sustainability: Reduces water waste and minimizes pollution discharge.

-

Economic Efficiency: Extends equipment lifespan by preventing scaling and corrosion.

Applications

-

Municipal: Public water supply and sewage treatment.

-

Industrial: Boiler feedwater, process water, and effluent management.

-

Residential: Home filtration, softening, and purification systems.

Innovations

Modern water treatment equipment increasingly integrates smart technologies, such as IoT-enabled sensors for real-time monitoring and AI-driven optimization of energy and chemical usage.

Conclusion

Water treatment equipment is indispensable for safeguarding water resources and supporting sustainable development. By selecting the appropriate technology tailored to specific needs, industries and communities can ensure water security, regulatory compliance, and ecological responsibility in an era of growing water scarcity.

Tel:+86 17731732115

Whatsapp:+86 17731732115

Fax:+86 17731732115

Email:manager@sailingmachinery.com

Address:Industrial Zone, Yunhe District, Cangzhou City, Hebei Province, China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours